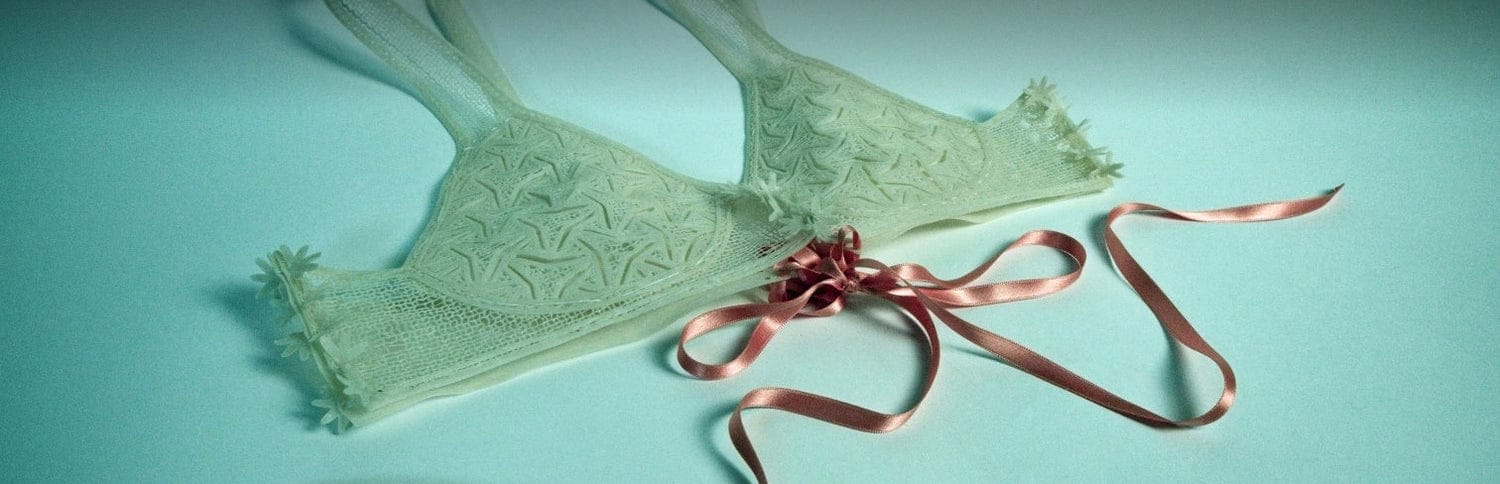

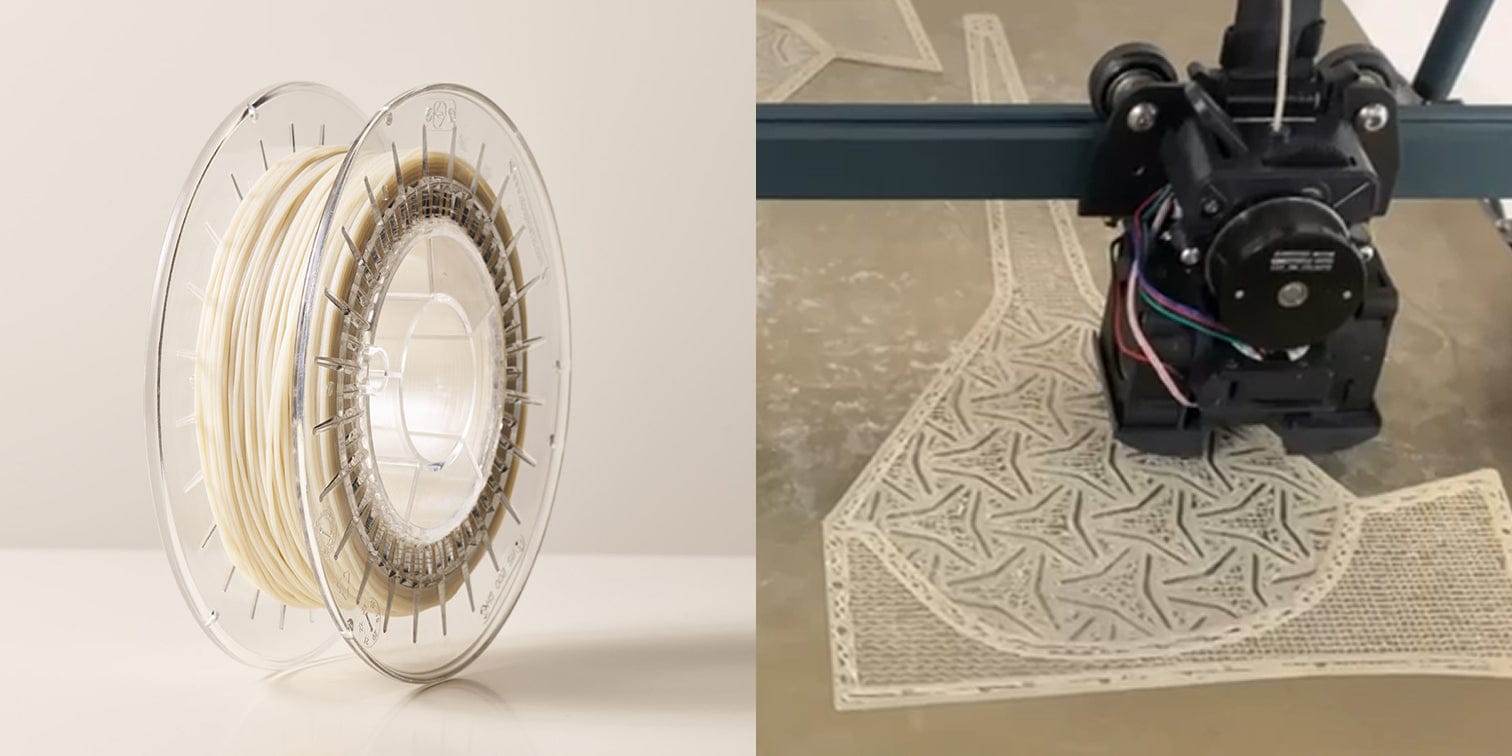

A revolutionary step forward for sustainable fashion and body-inclusive design has emerged from a cross-disciplinary collaboration between Colombian designer Neyla Coronel and bio-based material innovator Balena. The result: the world’s first 3D-printed, fully compostable bra made from Balena.Filaflex, a flexible and biodegradable filament co-created with Recreus.

Neyla’s project, developed during her postgraduate studies at Fabricademy, is more than an experiment in form. It challenges the fashion industry’s reliance on standardised sizing and static beauty ideals, offering instead a garment that adapts to the wearer’s unique form and movement. Designed using parametric modelling, 3D scanning, and auxetic geometries, the bra custom-fits the body while promising comfort, durability, and end-of-life biodegradability.

Raised in Colombia, Neyla’s personal journey informed the project’s emotional and functional dimensions. Frustrated by the lack of intimate wear that truly fit—not just in size, but in feeling—she asked a bold question: what if the bra adapted to the woman, not the other way around?

The technical heart of her innovation is an auxetic structure that expands and contracts in harmony with the body. This adaptive geometry would be impossible without the right material. After early prototypes in PLA and TPU proved too rigid or environmentally unsound, she turned to Balena.Filaflex—a biobased, compostable, and recyclable filament designed for high performance and flexibility. “Its softness and elasticity enabled complex, body-responsive forms that move with the wearer,” she explained.

Through the support of Footwearology, who facilitated her access to the material, Neyla was able to fully realise her concept. The final garment offers a solution to the often-overlooked needs of those whose bodies defy conventional sizing charts. Just as significantly, it introduces a model for fashion design that is inclusive, emotionally intelligent, and aligned with regenerative systems.

Balena.Filaflex, developed in partnership with Spanish filament maker Recreus, is more than a 3D printing material—it’s a catalyst for a new design language. Neyla’s work illustrates how bio-based materials can empower designers to create intimate wear that is sustainable, adaptable, and deeply personal.

The project also opens doors to participatory design. By allowing users to adjust parameters such as strap length, pattern density, and expansion zones, Neyla envisions a future where wearers co-create their own fit. “I don’t want this project to be only mine,” she says. “It should be a shared space—from a woman to women—where design becomes both personal and empowering.”

Looking ahead, Neyla is expanding her focus beyond intimate wear to other body-responsive products such as footwear and furniture. “Balena.Filaflex showed me how material science can support designs that are both sustainable and human,” she reflects.

This project marks a significant moment for circular fashion and for the role of materials in shaping new design paradigms. By bridging technical innovation with personal storytelling, Neyla Coronel and Balena offer a compelling vision of where fashion is headed: towards a future that’s regenerative, inclusive, and designed for life.